As with any other pharmaceutical drug, medicinal cannabis needs to undergo rigorous testing to ensure that it is both fit for human consumption and is delivered at the right potency to provide the medical outcomes that it is being taken for. Up to now, testing of cannabis has been sporadic and there is no universally agreed standard to which producers or testing labs must adhere to. Where regulations are in place responsibility for the testing is generally at a smaller number of approved independent testing laboratories.

Testing with HPLC

There are two main methods that cannabis labs use to test for potency: gas chromatography and liquid chromatography. These are both useful methods for separating and quantifying small compounds, but there are some key differences.

There are two main methods that cannabis labs use to test for potency: gas chromatography and liquid chromatography. These are both useful methods for separating and quantifying small compounds, but there are some key differences.

As the name suggests, gas chromatography (GC) uses gas to carry the sample through the instrument for separation and detection. Gas chromatography instruments tend to be cheaper and therefore more accessible.

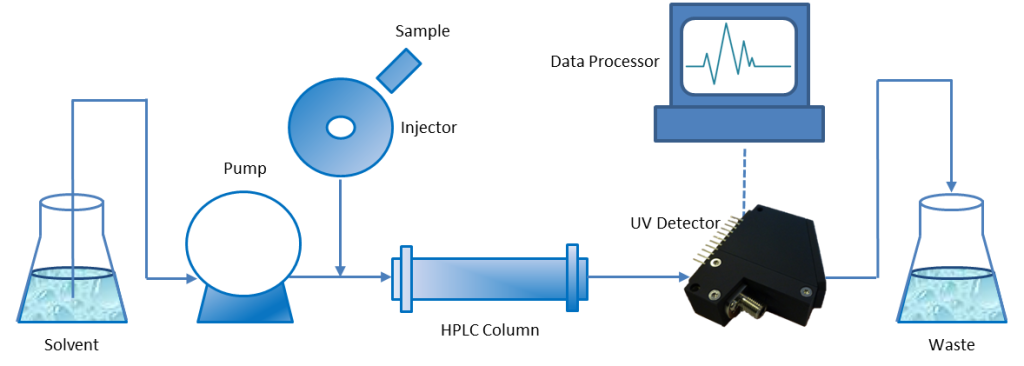

However, many cannabis testing labs prefer high-performance liquid chromatography (HPLC). HPLC relies on a liquid medium to carry the sample through the instrument for separation and detection. Unlike GC, HPLC can detect THCA and CBDA. THCA and CBDA are precursors to THC and CBD respectively and may have therapeutic properties of their own.

One of the core issues with cannabis quality is the use of pesticides. In 2016, the Ministry of Environment and Health in the Netherlands reported that over 90 percent of cannabis plants had pesticides on them. Illegal producers of cannabis can supply cannabis unhindered with potentially harmful contaminants such as fungi or pesticide residues that are potentially threatening to health. It is evident that there is a need to develop appropriate analytical techniques for quality assurance and quality control laboratories for cannabis testing.

Meeting Safety Standards

Cannabis goes through a long journey from seed to plant to processing before finally ending up on the shelf as a packaged retail product. Along the way, there are many potential sources of contamination.

Heavy metals found in soil can be absorbed through the roots and become concentrated in the plant. The natural moisture in cannabis can foster the growth of microbes. Pesticides and processing chemicals can be left behind at unsafe levels.

Any potential contaminant poses a risk to the health of consumers. Cannabis testing is the only way to ensure that your products are free of contamination and safe for consumption.

Quality Control

Want to make sure that you’re offering the highest quality and most consistent product possible? Then you need to be testing.

Consumers are looking for products they can dose easily and that give predictable effects. Cannabis testing allows you to put a number on characteristics like potency and contaminants so that your customers know exactly what they’re getting.

Some cannabis testing labs even offer quality assurance testing so that you can improve your processes and prevent regulations issues down the line.

Meeting State Regulations

Assuring the quality and safety of your product for your customers is obviously a top priority. But aside from the desire to provide high quality flower, edibles, and other cannabis products, growers, manufacturers, and dispensaries now also face a legal obligation.

With the passage of SB1494, Arizona approved the establishment of an Advisory Council for Marijuana product testing. This council will, working with industry, patients and other will establish cannabis testing requirements and protocols for testing by a state-accredited lab.

The likely testing requirements will differ depending on the type of product. For example, inhalable cannabis products like flower may require testing for the following characteristics:

- Cannabinoids (potency)

- Terpenes

- Pesticides

- Residual solvents

- Heavy metals

- Moisture content/water activity (R&D Shelf Life testing)

- Mycotoxins

- Microbials

Halo Infusions & Extractions employs a state-sanctioned and approved use of multiple Certificates of Analysis for infused edible products, consisting of:

- Full Panel tests of Cannabinoid Potency, Pesticides, Heavy Metals, Residual Solvents, and Microbials and their related Mycotoxins, and

- Final Product tests of Potency and Microbial/Mycotoxins

We employ a two test approach to minimize overall costs by testing the source infusion material (flower or extract) for impurities at the beginning of infusion production, rather than the end. This results in higher quality and increased consumer safety.